Designing Beyond Traditional Manufacturing

Lately, I’ve been deeply exploring the unique advantages of Fused Deposition Modeling (FDM) 3D printing. It’s a technology that truly opens up a new frontier for design, allowing for the creation of objects that are simply impossible to make with conventional manufacturing methods like injection molding or CNC machining. A geometrically simple part on the outside can hide an internal complexity that makes it incredibly difficult, or even impossible, to produce by any other means.

Although I haven’t done much of it in my professional career, my background is rooted in years of 3D modeling and animation. Transitioning that mindset to product design has been a fascinating shift. It’s one thing to create a flawless digital asset and it’s another to consider the real-world physics and manufacturing constraints of a tangible object. Learning to see everyday items through the lens of how they are designed, molded, and assembled has been a profound change in perspective.

For the past few years, I’ve used FDM printing for a variety of projects, from work-related models to simple, practical items around the house. I started with accessible designs; lampshades, custom cell phone holders, and organizational tools. This quickly evolved into developing more functional items, such as affordable accessories for prohibitively expensive healthcare devices, demonstrating how this technology can bridge critical accessibility gaps.

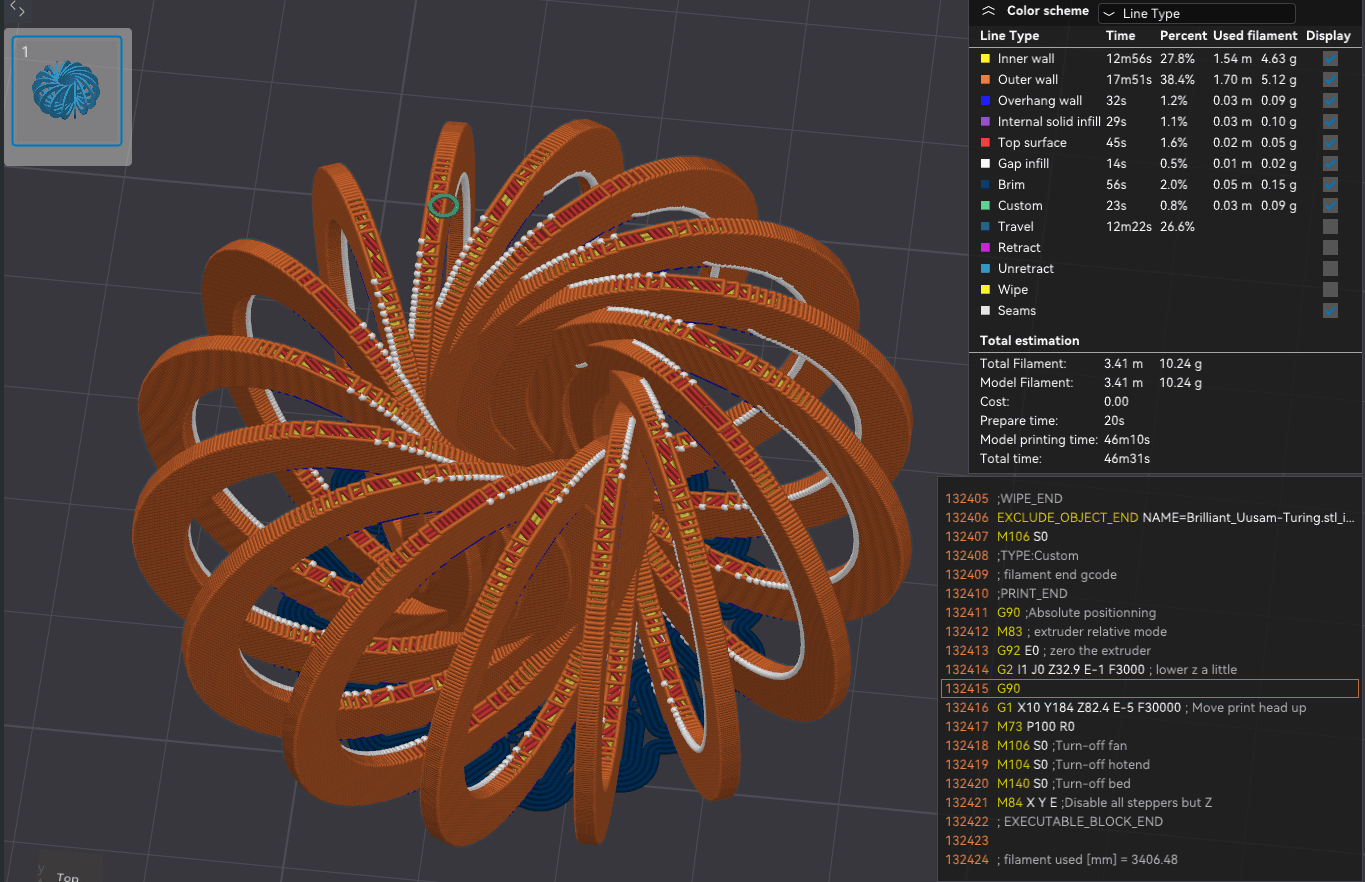

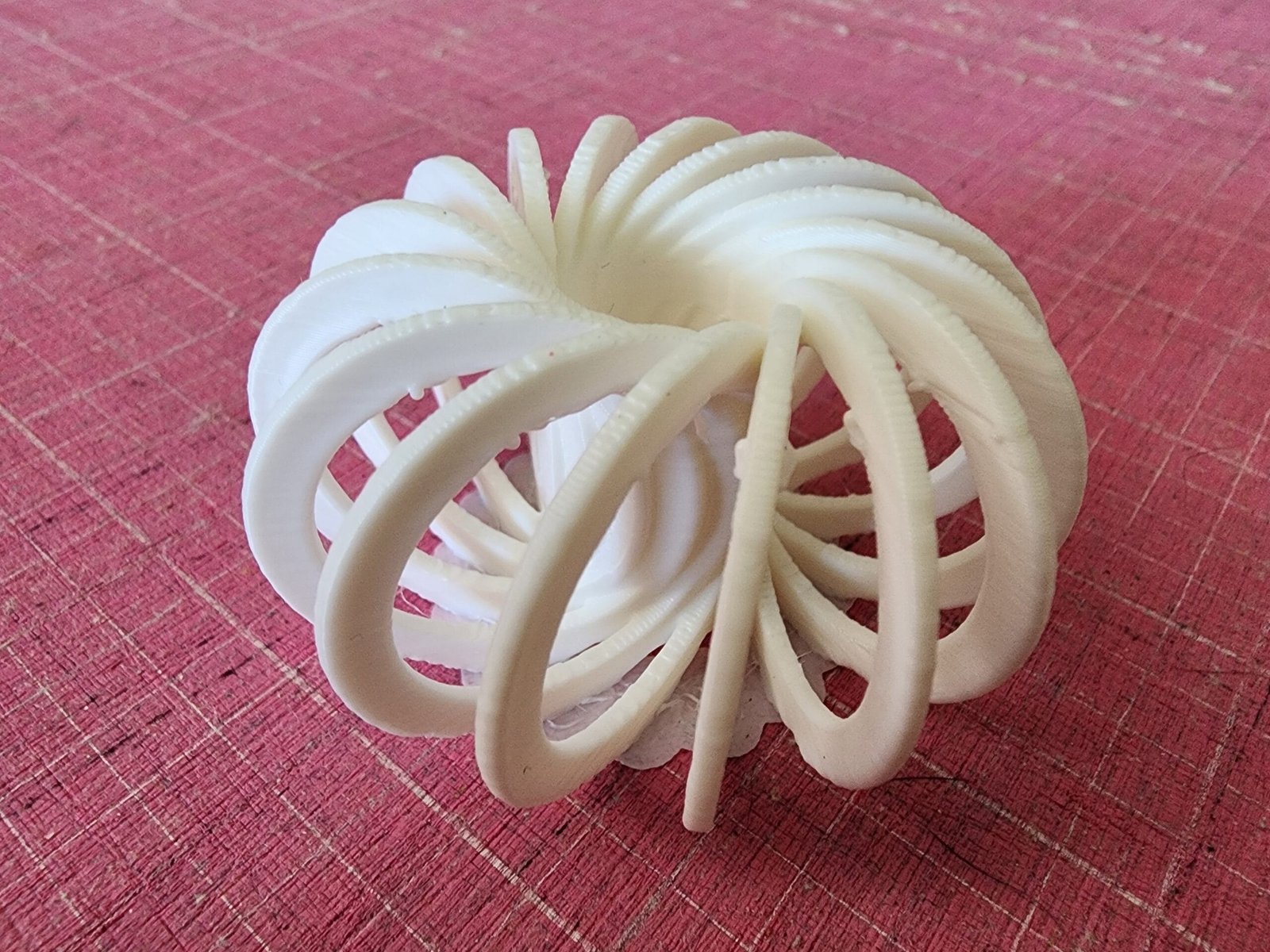

An FDM 3D printed toroid made of concentric circles.

Unlocking Geometries Impossible with Other Methods

The true power of FDM lies in its additive nature and building an object layer by layer from the ground up. This is fundamentally different from subtractive methods (like CNC milling, which carves away material) or formative methods (like injection molding, which shapes molten material in a cavity). This distinction is what allows FDM to create features that other processes cannot.

- Complex Internal Geometries: Imagine creating a part with intricate internal cooling channels that twist and turn, or a lightweight yet strong component filled with a complex internal lattice structure (like a gyroid infill). With injection molding, you can’t create these sealed internal voids because the solid mold core couldn’t be removed. FDM builds these internal features as it prints, making them not only possible but practical.

- Part Consolidation: An assembly that traditionally requires ten different parts, plus screws and glue, can often be redesigned and printed as a single, complex piece. This reduces assembly time, eliminates potential points of failure, and can create a stronger, more lightweight final product.

- Draft Angles and Supports: FDM printing removes the need for draft angles (the slight tapers required for injection molding), which allows for true vertical walls. However, this introduces the need for temporary support structures to hold up steep overhangs during the printing process. These supports add time and material to a print and must be removed afterward, which can impact the final surface finish.

Democratizing Innovation

While it’s fantastic for printing helmets and detailed miniatures, the applications of FDM extend far beyond hobbyist creations. Its real strength lies in democratizing innovation. It empowers designers, engineers, and entrepreneurs to prototype and iterate on their ideas without needing a massive budget for tooling or access to a full-scale machine shop.

With a simple desktop printer, anyone can move from a digital concept to a physical, functional prototype in a matter of hours. This ability to rapidly test, refine, and re-test an idea drastically accelerates the development cycle and lowers the barrier to entry for bringing new products to life. FDM printing isn’t just another manufacturing tool, it’s a catalyst for creativity and a powerful platform for problem-solving.